calculation of ball filling ratio in grinding mill ...

calculation of ball filling ratio in grinding mill manufacturer in Shanghai, China. calculation of ball filling ratio in grinding mill is manufactured from Shanghai ...

WhatsApp)

WhatsApp)

calculation of ball filling ratio in grinding mill manufacturer in Shanghai, China. calculation of ball filling ratio in grinding mill is manufactured from Shanghai ...

Optimization of mill performance by using online. previously, at a mill stop, the measurement of ball charge filling degree could beof the charge.

the maximum reduction ratio of sag mill. ... Ball Filling Percentage reduction, as a result of their comparative or investigation on the ball filling ratio ...

Optimization of mill performance by using online ball and pulp saimm internal mill diameter ''Di''. By calculating the ratio ''H/Di'' and using the graph below.

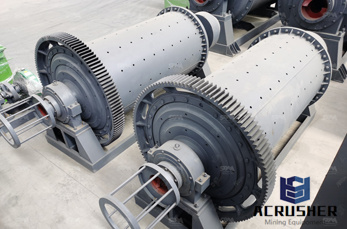

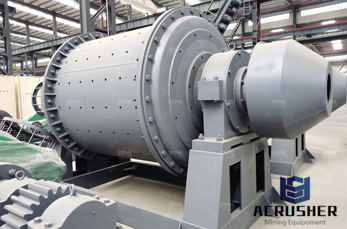

Ball mill. A typical type of fine grinder is the ball mill. A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal ...

What is ball milling? A ball mill is a type of grinder used to grind materials ... Ball milling should be considered as a potentially

Internal diameter Internal length Filling degree Spec. media weight Mill speed Drive efficiency mech. Drive efficiency electr. Mill throughput Fineness product ...

The influence of several grinding parameters such as charged material volume, ball filling ratio, and mill rotation speed on energy efficiency of fine grinding of ...

Highly accurate measurement of filling levels and . ... filling ratio so for a long time efforts havebeen made to ... The ball mill is operated empty and then full ...

Ball Filling and Ratio of Feed to Grinding Balls ... Grinding experiments were conducted in a laboratory scale ball mill with variations of ball filling, 20%, 30%,

calculate the charging in cement mill pdf . One can calculate W m from the power draw of a mill measured at shaft For cement clinker a can be set to ball charge ...

Ball Mill Group Calculation Feed capacity → Mill dimensions Filling ratio ... derivation to calculate critical speed of ball mill . design calculation of ...

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction needs.

variation is between – % which is lower than mill ball filling percentage, according to the designed ... or investigation on the ball filling ratio

filling ratio for a ball mill – The QA wiki. In this,the filling material is replaced by using suitable placebo (Lactose,PEG) along with micribological .

Ball mill is the main equipment of ore dressing process, and it is widely used in mining, metallurgy, building materials, refractory, cement, chemical and thermal ...

MODELING THE SPECIFIC GRINDING ENERGY AND BALLMILL SCALEUP ... The fraction of mill filling f L 2. ... ratio, for feed size D f .

Grinding Media Ratio In Cement Mill ... 10 Jan 2014 ... ball mill for cement grinding able for large grinding media ... the L/D ratio, ball charge filling ratio, ...

Cement Mill Ball Mill Dynamics Kiln Control Theory ... The fraction of critical speed at which cataracting onsets is a function of the filling ratio and lifter design.

volume of ball in ball mill. About lead ball mill media. Weight, and size? ... ball filling ratio, and mill rotation speed on energy efficiency of ...

Keywords: Miduk Copper Concentrator, SAG Mill, Ball Filling Percentage. Introduction ... calculation in filling ratio for ball mill; ball mill grinding media;

A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls ...

Effect of ball mill grinding parameters of hydrated lime fine grinding ... The influence of several grinding parameters such as charged material volume, ball filling ...

Ball mill ball charge degree of ball filling calculation. ... Documents Similar To Ball Mill Degree of Filling Calculation. ... Raw Meal to Clinker Ratio.

WhatsApp)

WhatsApp)